Value Added Processes

Fit-for-purpose processing for steel custom-tailored to your application’s requirements.

Jade Sterling Steel provides our customers with a trusted source for steel stock enhanced through a variety of value-added processes for bar and wire rod products.

With exclusive availability agreements with numerous processors, we have the capacity to provide material in a timely manner at pricing well below market rates.

The right value-added processes can provide outstanding value, helping customize steel to specific engineering requirements without resorting to a more costly alternative.

Valued Added Processes for Steel Bar and Wire Rod

Our team can work with you to determine which of the value-added processes outlined below are right for your application.

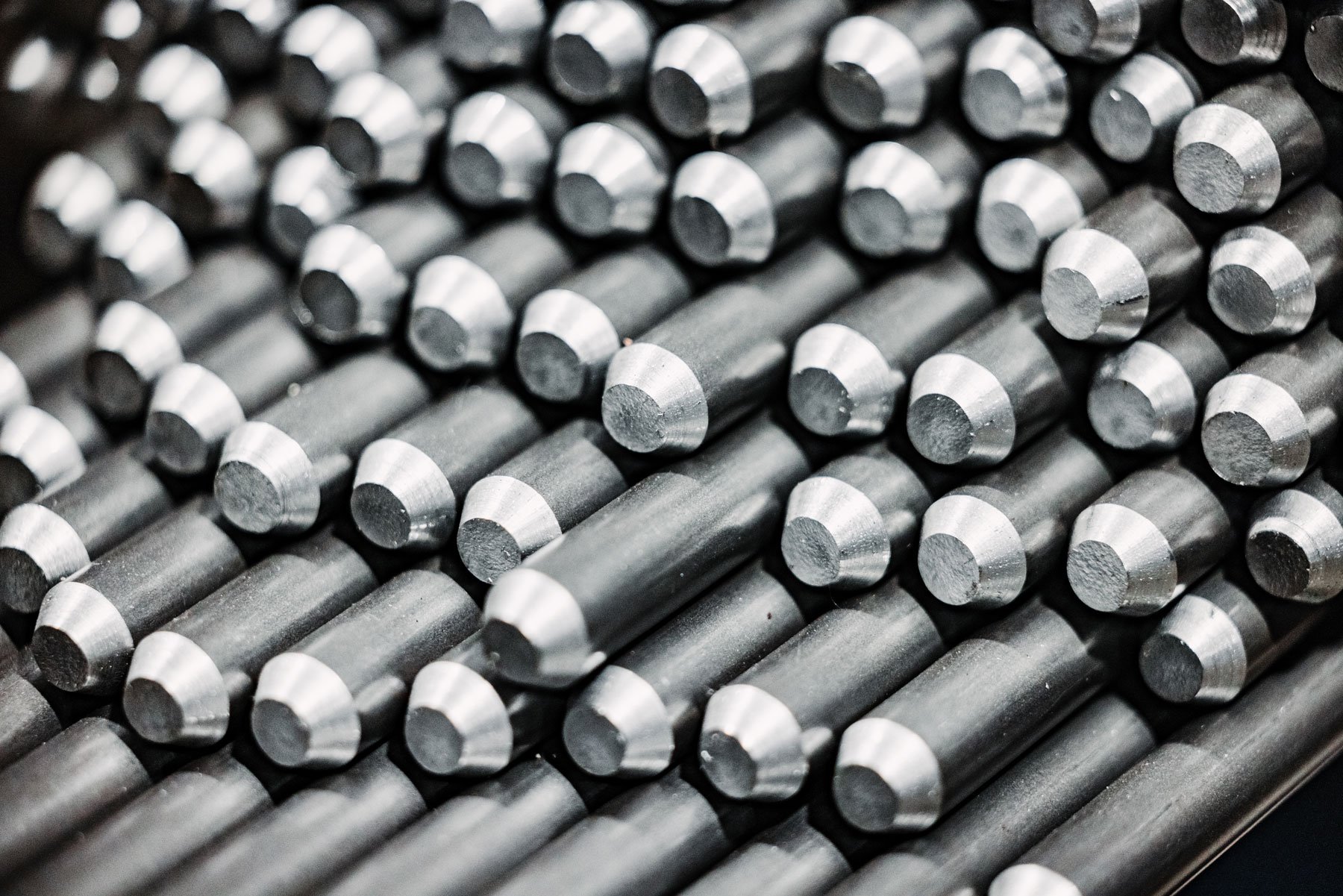

Cold Drawing

Cold drawn wire and bars offer improved size accuracy, finish, straightness, and mechanical properties compared to hot rolled steel. Learn more about cold drawn steel bar.

Turn, Polish, and Precision Grinding

Turned and polished steel offers a smoother, defect-free finish for even hot rolled steel, in addition to a high level of concentricity and optimum straightness. Learn more about turn and polish.

Rough Turned

Rough turning a material removes the bar's surface layer, generally eliminating decarburization, seams, slivers, and other surface imperfections.

Heat Treating

Heat/Thermal treatment techniques include annealing, normalizing, quenching/tempering, and stress relieving.

Quenching and Tempering

This process involves heating a steel bar above the austenitic transformation temperature before rapidly quenching it using oil or water to increase hardness, and then tempering it to reduce brittleness.

Machining

Machining services can create custom shapes to support unique applications for steel bars and wire rods.

Production Saw Cutting

Precision saw cutting can be used to remove unwanted material and shape steel bars to application-specific requirements.

Production Chamfer

Chamfering is a machining process that can be used to remove edge portions of steel bar to create a desired shape.

Wire Processing

Wire processing services can help create specific meet specific requirements for wire-based applications.

Eddy Current Testing

Eddy current testing makes use of electromagnetic induction to identify defects in the tubing.

Shot Blasting

This process is a surface treatment technique that uses a high-pressure spray of abrasive “shot” to create steel materials to create a smooth surface.

To learn more about any of these value-adding processes or how they can be used to improve the performance of your product, contact our team.

Need help choosing the right value added process for your steel bar or wire rod?

With a broad selection of value processes through our extensive network of suppliers, Jade Sterling Steel can help source the material best suited for your application and support your business with a timely, reliable supply of quality steel.

If you need help selecting the right product, our team is here to help.

Please contact us here with your questions or request a quote using the button below.